Fibre Optic Splicing - Termination Safe Work Method Statement

- Instant Document Delivery via Email.

- Add your logo easily.

- Add or delete information to any SWMS template.

- Customisation instructions provided.

- Complies with Australian & New Zealand legislation.

- Microsoft Word Format (Fully editable).

- Only pay once (no subscriptions required).

Fibre Optic Splicing - Termination Safe Work Method Statement

This Fibre Optic Splicing - Termination Safe Work Method Statement (SWMS) covers hazards and controls associated with the planning and preparation of the activity and operation involved with repairing, splicing or building a new joint in fibre optic cabling adjacent to roads and, subsequent placement in a pit or manhole.

This SWMS covers High-Risk Construction Work (HRCW) controls related to:

- Mobile plant movement

- Asbestos disturbance

- Pressurised gas distribution mains or piping chemical, fuel or refrigerant lines energised electrical installations or services

- Work carried out adjacent to a road, railway or shipping lane, traffic corridor

Additional controls are included for Electrical Equipment, Elevated Levels, Slips, Trips & Falls, Hazardous Substances, Out-of-Hours/Night Work, Hazardous Manual Tasks, Outdoor Work & Environmental Considerations.

Job Steps Covered in Fibre Optic Splicing - Termination SWMS:

(includes potential hazards and control measures)

- Planning

- Training

- Working Outdoors

- Arrival On-site & Assess On-site Conditions

- Work Area Set-up

- Environment

- Housekeeping

- Manual Tasks

- Working with Powered & Non-powered Tools

- Hazardous Substance/Chemical Use

- Manhole/Pit Work

- Asbestos Disturbance

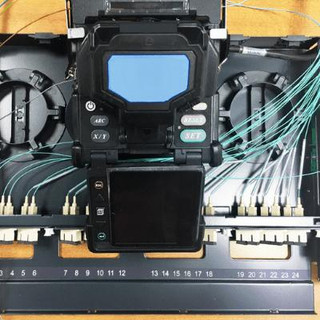

- Fibre Splicing & Termination

- Test & Commission

- On Completion

- Emergency Response

- Instant Document Delivery via Email.

- Add your logo easily.

- Add or delete information to any SWMS template.

- Customisation instructions provided.

- Complies with Australian & New Zealand legislation.

- Microsoft Word Format (Fully editable).

- Only pay once (no subscriptions required).

Fibre Optic Splicing - Termination Safe Work Method Statement

This Fibre Optic Splicing - Termination Safe Work Method Statement (SWMS) covers hazards and controls associated with the planning and preparation of the activity and operation involved with repairing, splicing or building a new joint in fibre optic cabling adjacent to roads and, subsequent placement in a pit or manhole.

This SWMS covers High-Risk Construction Work (HRCW) controls related to:

- Mobile plant movement

- Asbestos disturbance

- Pressurised gas distribution mains or piping chemical, fuel or refrigerant lines energised electrical installations or services

- Work carried out adjacent to a road, railway or shipping lane, traffic corridor

Additional controls are included for Electrical Equipment, Elevated Levels, Slips, Trips & Falls, Hazardous Substances, Out-of-Hours/Night Work, Hazardous Manual Tasks, Outdoor Work & Environmental Considerations.

Job Steps Covered in Fibre Optic Splicing - Termination SWMS:

(includes potential hazards and control measures)

- Planning

- Training

- Working Outdoors

- Arrival On-site & Assess On-site Conditions

- Work Area Set-up

- Environment

- Housekeeping

- Manual Tasks

- Working with Powered & Non-powered Tools

- Hazardous Substance/Chemical Use

- Manhole/Pit Work

- Asbestos Disturbance

- Fibre Splicing & Termination

- Test & Commission

- On Completion

- Emergency Response