Who Is SafetyDocs?

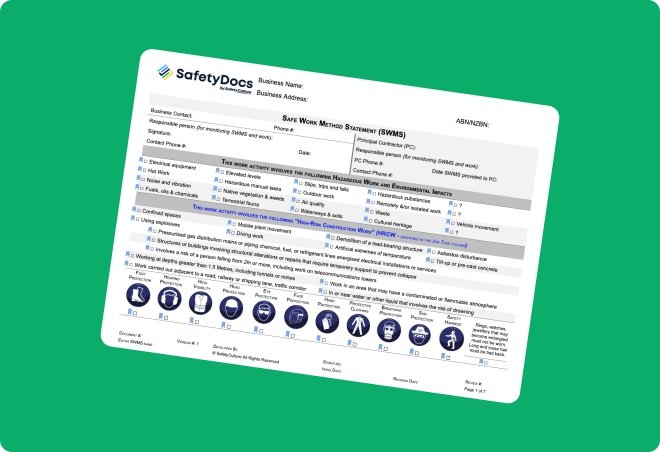

Founded in 2004, SafetyDocs by SafetyCulture is one of Australia’s leading providers of Occupational Health and Safety Documents.

After witnessing the tragedy of workplace incidents as a private investigator, our founder, Luke Anear, created SafetyDocs by SafetyCulture to become one of Australia’s largest providers of workplace health and safety documentation. As the company and technology developed, Luke then recruited a team to help develop a mobile solution for safety in the workplace - iAuditor.

Over 35,000 Australian & New Zealand businesses have relied on SafetyDocs by SafetyCulture for their safety document needs. Our safety solutions assist you with legislative compliance, meeting tender requirements and the needs of your clients. With our content-rich documents designed to save your business the time, money and resources of producing them yourself.